INVESTMENT POWDER FOR TIRE MOLD CASTING

POWERCAST “T” is a superior quality, non-foamed investment molding plaster developed for the casting of aluminum alloys via the perminant mold process. Engineered to provide the highest quality molds for the vulcanization of tires, POWERCAST “T” is a consistent, easy to use tire mold casting plaster that provides sharper, detailed replication of even the most complex tread configurations.

INSTRUCTIONS FOR USE• User friendly, easy to mix formula,

• Expansion &shrinkage values are strictly controlled

• Added surface tension reducer assists in removing trapped air bubbles

• Precise particle sizing for a far smoother, as cast surface

• Excellent mold permiability

• Formula greatly reduces the instance of mold cracking and warping

• Provides tight tollerances

• Highest batch to batch consistency

• Reduces rejects. saves time and money spent in finishing

Used by quality conscious casters worldwide, Prestige “POWERCAST “T” has proven to be a truly superior gypsum bonded investment

for tire mold casting “PERFECTION IN CASTING

TECHNOLOGY” Powercast “T” comes in 22.5Kg. Plastic lined Poly Sacks or 1Ton Heavy Duty Bulk Bags

| Powder: Water Ratio (50% - 52% | Powder (Kg.) | Water (cc.) | Powder (Lb.) | Water (cc.) |

|---|---|---|---|---|

| Automatic Vac. Mixing | 1 | 500 | 1 | 227 |

| Conventional Mixing | 1 | 520 | 1 | 236 |

| Water Temperature ˚C | 21-24 | 21-24 | 21-24 | 21-24 |

Increasing the powder amount 1% will decrease the total working time for approximately 30 seconds.

| Automatic Vac. Mixing Mach. | Minutes |

|---|---|

| Accurately Weigh Powder / Water | ------ |

| Add Powder to Water | ------ |

| Mixing & Vacuuming | 5 |

| Pour into Flask | 3 |

| Vacuum Invested Flask | 3 |

| Total Working Time | 11 |

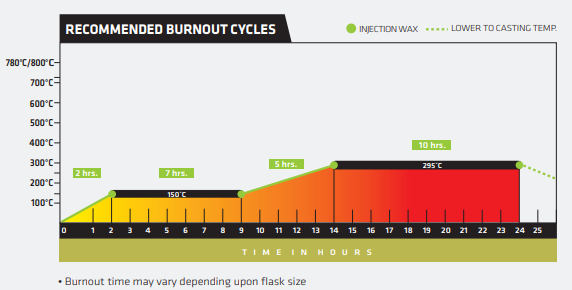

Allow to sit undistributed for 120-150 minutes

before burnout

| Conventional Mixing Mach. | Minutes |

|---|---|

| Accurately Weigh Powder Water | ------ |

| Add Powder to Water & Mix | 5 |

| Vacuum the Bowl | 1 |

| Pour into Flask | 2 |

| Vacuum Invested Flask | 3 |

| Total Working Time | 11 |

Allow to sit undistributed for 120-150 minutes

before burnout