CASTING FOR BRASS AND BRONZE

Prestige ROYAL-CAST™ is another breakthrough by Certus to provide the industry with a low cost, high quality gypsum bonded investment developed specially for the casting of low & high production Brass & Bronze jewelry castings. To ensure the highest quality and batch to batch consistency, Royal Cast incorporates high purity, specially graded refractory minerals along with proprietary control additives that when used as directed, eliminates watermarks and air bubbles from forming on the cast surface, thus providing the user with sharper, smoother detailed castings that require far less time in finishing over all other leading brands.

FEATURES

• Easy to use – Mixes a thin, creamy, easy to pour consistency

• High purity – Uses only the world’s finest raw materials from America & Europe

• Control – Incorporates special, proprietary wetting and antifoaming agents

for smooth, sharp, detailed castings

• Variable w/p ratios – Can be used for thick to thin designs using 38%-40%

water to powder ratio

• Superior mold strength – High green and fired strength for stronger molds, great

for both low and high volume shops

• High Heat resistance – Resistant to thermal shock during burnout

• Sharper reproduction of detail – Investment particles sized to capture the finest

of details in brass & bronze

Independent tests performed by some of the world’s best known casting companies show that Prestige “ROYAL CAST” has proven to be a truly superior investment for casting brass & bronze.“PERFECTION IN JEWELRY CASTING TECHNOLOGY” Royal Cast comes in 22.5Kg. Poly Sacks with plastic liner

| Powder: Water Ratio (38% - 40%) | Powder (Kg.) | Water (cc.) | Powder (Lb.) | Water (cc.) |

|---|---|---|---|---|

| Automatic Vac. Mixing | 1 | 380 | 1 | 172 |

| Conventional Mixing | 1 | 400 | 1 | 181.6 |

| Water Temperature ˚C | 21-24 | 21-24 | 21-24 | 21-24 |

• Increasing the powder amount 1% will decrease the total working time for approximately 30 seconds

| Automatic Vac. Mixing Mach. | Minutes |

|---|---|

| Accurately Weigh Powder / Water | ------ |

| Add Powder to Water | ------ |

| Mixing & Vacuuming | 5 |

| Pour into Flask | 2 |

| Vacuum Invested Flask | 1 |

| Total Working Time | 8 |

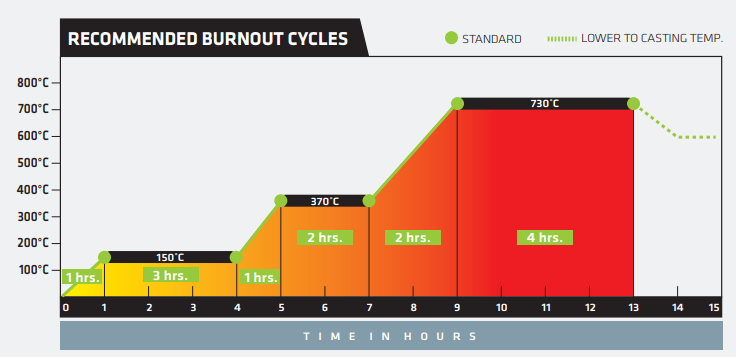

• Allow to sit undistributed for 90-120 minutes before burnout

| Conventional Mixing Mach. | Minutes |

|---|---|

| Accurately Weigh Powder Water | ------ |

| Add Powder to Water & Mix | 4 |

| Vacuum the Bowl | 1 |

| Pour into Flask | 1 |

| Vacuum Invested Flask | 2 |

| Total Working Time | 8 |

• Allow to sit undistributed for 90-120 minutes before burnout