FOR CASTING SILVER BRASS, AND BRONZE

Prestige SIGMA™ is a high value, low cost gypsum bonded investment powder developed by Certus to provide the user and industry with an investment powder engineered specially to eliminate costly surface defects associated with casting the most difficult designs and shapes cast in silver and bronze.

FEATURES

• Uses the highest purity raw materials available

• Variable water to powder ratio, 38 – 40/100 for thick to thin designs

• User friendly formula, easy to mix and use

• Superior thermal shock resistance to temperature. Highly resistant to flashing

and cracking

• Special proprietary control additives easily remove air from the investment slurry

and pattern surface to provide super smooth, bubble free castings time after time

• Provides extra smooth, dense, flash free castings

• Easy removal during water quench.

• Better casting results, even when less than perfect mixing techniques are observed

• ZERO defects policy. All batches test cast in silver to ensure perfect quality

before shipping

Independent tests performed by some of the world’s best known casting companies, Prestige “SIGMA” has proven to be a truly superior investment for casting silver. “PERFECTION IN JEWELRY CASTING

TECHNOLOGY” Sigma comes packaged in 22.5Kg. Plastic lined Poly Sacks, Ergonomic 22.5Kg. Plastic Drums and 45Kg. Heavy duty reusable Plastic Drums for safe containment of used investment.

| Powder: Water Ratio (38% - 40%) | Powder (Kg.) | Water (cc.) | Powder (Lb.) | Water (cc.) |

|---|---|---|---|---|

| Automatic Vac. Mixing | 1 | 380 | 1 | 172 |

| Conventional Mixing | 1 | 400 | 1 | 181.6 |

| Water Temperature ˚C | 21-24 | 21-24 | 21-24 | 21-24 |

• Increasing the powder amount 1% will decrease the total working time for approximately 30 seconds

| Automatic Vac. Mixing Mach. | Minutes |

|---|---|

| Accurately Weigh Powder / Water | ------ |

| Add Powder to Water | ------ |

| Mixing & Vacuuming | 5 |

| Pour into Flask | 2 |

| Vacuum Invested Flask | 1 |

| Total Working Time | 8 |

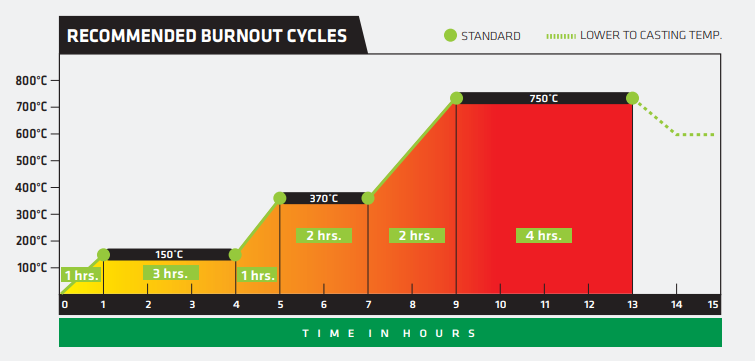

• Allow to sit undistributed for 90-120 minutes before burnout

| Conventional Mixing Mach. | Minutes |

|---|---|

| Accurately Weigh Powder Water | ------ |

| Add Powder to Water & Mix | 4 |

| Vacuum the Bowl | 1 |

| Pour into Flask | 1 |

| Vacuum Invested Flask | 2 |

| Total Working Time | 8 |

• Allow to sit undistributed for 90-120 minutes before burnout